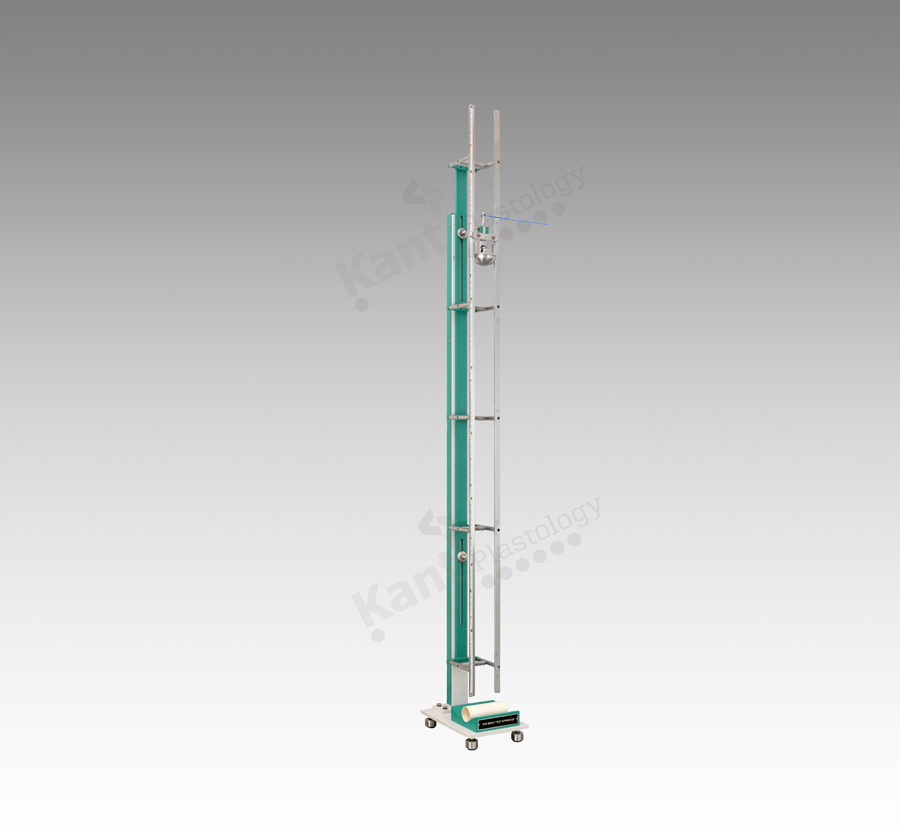

Kant Plastology offering a commendable range of Digital TENSILE TESTING MACHINE for determines the mechanical strength of various products like Plastic Pipe, HDPE/PP Tape – Fabric, Plastics rope and many more plastics products. The machine is manufactured from high grade raw material with latest technology which is inspected properly by our highly professional engineers. The offered machines owing the feature like Touch screen LCD display with PLC base HMI control, precision load-cell with durable and sturdy structure of machine. Kant Plastology provide the entire range of TENSILE TESTING MACHINE with multitude of sizes, designs and other related customize specification and designs.

Specification

| MODEL (K-TTM-02LC-HMI) | |

| Applicable For | Specially designed for Wovensack Tape & Fabric made from HDPE/PP/LDPE |

| Test Capacity | Loadcell 1: 500 kgf / 5 kN, Loadcell 2: 50 kgf / 500 N |

| System status | Touch screen HMI synchronize with PLC to indicate the value of Load, Elongation, Test type & Testing speed etc. |

| Motor | 2000 RPM servo motor controlling through servo drive device |

| Test jaws | Individual testing Grip / Jaws for Tape & Fabric reduces slippage during test |

| No. of screws | Ball screw-nut assembly driven through reputed make gear box |

| Load cell | Dual Loadcell ‘S’ type of reputed make |

| Load cell unit | kgf / N |

| Cross head travel | 300 mm with least count of 0.01 mm |

| Speed | 5mm to 500mm variable testing speed through servo drive |

| Result | Maximum load, Maximum elongation, Break load, Tensile Strength at Max., % Elongation at Max., Tensile Strength at Break value with graphical data can be printout through dot-matrix printer available on front panel |

| Paint | Powder coated |

| Power supply | 440V AC, Three phase, 50Hz |